Advantages of Boron Trifluoride Ethylamine Complexes

Product description

Chinese name: boron trifluoride ethylamine complex

Chinese alias: Boron trifluoride-ethylamine

English name: Boron Trifluoride-Ethylamine complex

CAS No.: 75-23-0

Molecular formula: C2H7NBF3

Molecular weight: 112.8899

Product application.

Used as a catalyst in organic synthesis, epoxy resin curing agent, also used in the manufacture of rocket high-energy fuel. Boron trifluoride-ethylamine complex (75-23-0) can be used as latent curing agent of epoxy resin. Dosage 3 parts, below 100 curing speed is very slow, above 120 is very fast curing, and accompanied by exothermic. The heat deflection temperature of the cured product can reach 230, and the electrical property is good, but the impact strength is low, and the alkali resistance and humidity resistance is poor, so it is suitable for laminated products and casting materials. The resin cured with this product has semi-submerged characteristics, which is suitable for users to machine the prepreg parts before curing. This product and epoxy resin in curing can produce more ether bonds, increasing the toughness and adhesion of the product.

Additional resources:What are the top 5 benefits of using Oxybenzone?

Is Sodium Lauryl Ether Sulfate 70 Safe?

Is BMK Glycidate the Future of Pharmaceuticals?

Which is better colloidal silver or nano silver?

What is sodium cumene sulfonate 40 used for?

Exploring the Power of Diethyl Phenylacetylmalonate BMK Powder

What is plant cellulose?

Used as a latent curing agent for epoxy resin adhesives, the reference amount of 3 to 5 parts, to 3 parts is appropriate, 100g epoxy resin composition applicable period of 3 to 4 months. Curing conditions 120 / 2h + 150 / 3h, curing material heat deflection temperature 1.25 . After 120 / 3h + 200 / 1h curing treatment, heat deformation temperature up to 175 . With phenolic epoxy resin, heat deflection temperature 230. Aluminum oxide, aluminum hydroxide, silica, mica powder and other inorganic fillers can improve the applicable period of the composition. bpMEA has a large room temperature reactivity to alicyclic epoxy resins and polybutadiene epoxy resins. It can also be used as accelerator of DDS curing agent.

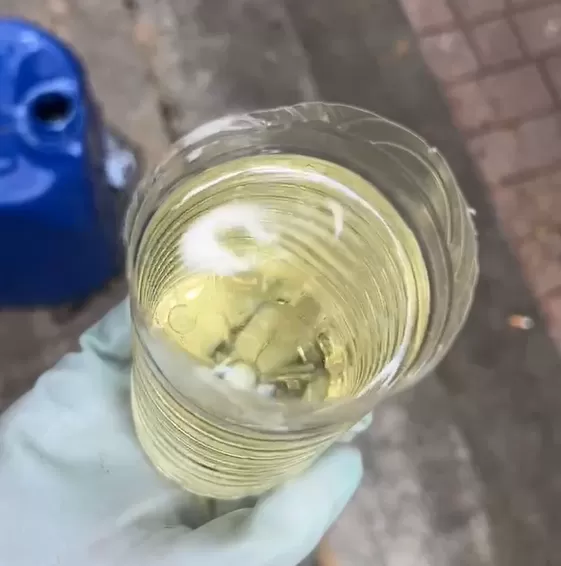

Hazardous properties.

It is hygroscopic and will hydrolyze and liquefy when placed in humid air and does not work as a curing agent. When heated, it decomposes into BF3 and ethylamine, ethylamine reacts with epoxy resin, and BF3 has the effect of improving the curing of epoxy resin; however, the decomposed BF3 is corrosive to metal.

More information please click here

More articles:

1-Chlorooctane: Understanding the Properties, Uses, and Implications

What is a spray adhesive used for?

10 best Pharmaceutical Raw Materials suppliers for purchase?

Your Ultimate Guide to Nano Zinc Oxide Sunscreen Benefits and Safety

Is 2-CHLORO-N,N-DIMETHYLETHYLAMINE HYDROCHLORIDE the new miracle weight loss supplement?

Unlocking the Best Deals: Magnesium Oxide Price Guide

Are HPMC-Grade Building Materials the Next Green Revolution?

Must-know facts about silver nano powder: benefits, uses, and safety

The Ultimate Guide to Understanding Polyacrylamide

Related Articles

Comments

0